Categories

- 3D PRINTING RESIN

- ABRASIVE MATERIAL

- ACRYLICS

- ADHESIVES, PRIMERS & CEMENT

- ALLOYS

- ARTICULATING

- ATTACHMENT, IMPLANTS & MAGNETS

- BOOKS

- BOXES & STORAGE

- BURNOUT & IMPRESSION POSTS

- CAD/CAM

- COMPOSITES

- CROWN & BRIDGE

-

DENTURE TEETH

- ACCESSORIES

- BREDENT VISIO LIGN SYSTEMS

- CLEANING

- KAIFENG SHADES A1 - A4

- KAIFENG SHADES B1 - B4

- KAIFENG SHADES C1 - C4

- KAIFENG SHADES D2 - D4

- MAIST SHADES A00 - A4

- MAIST SHADES B1 - B4

- MAIST SHADES C1 - C4

- MAIST SHADES D2 - D4

- PALA MONDIAL SHADES A1 - A4

- PALA MONDIAL SHADES B1 - B4

- PALA MONDIAL SHADES BLEACH

- PALA MONDIAL SHADES C1 - C4

- PALA MONDIAL SHADES D2 - D4

- SHADE & MOULD GUIDES

- TOOTH CABINETS

-

EQUIPMENT

- ACCESSORIES & SPARE PARTS

- AIR BLOWING

- BURNERS & TORCHES

- CASTING

- CLEANING

- COMPRESSORS

- DEFLASKING

- DUPLICATION

- DUST EXTRACTION

- FUME EXTRACTION

- GRINDER

- HANDPIECES & MICROMOTORS

- INDUCTION HEATERS

- INJECTION SYSTEMS

- LATHES

- LIGHT CURING

- LIGHTING

- MAGNIFICATION

- MILLING

- MIXING

- MODEL & ARCH TRIMMING

- PIN DRILLING

- PLASTER TRAPPING

- POLISHING

- POLYMERISATION

- PREHEATING FURNACES

- PRESSURE POLYMER UNITS

- SAND BLASTERS

- SHADE TAKING

- SINTER FURNACES

- SPARE PARTS

- STEAM CLEANER

- TURBINES

- VACUUM FORMER

- VIBRATORS

- WAXING

- WELDING

- IMPRESSION MATERIALS & TRAYS

- INFECTION CONTROL

-

INSTRUMENTS

- CALIPERS

- CERAMIC BRUSHES

- CERAMIC INSTRUMENTS

- COMPOSITE INSTRUMENTS

- HAMMERS

- HEMOSTATS & TWEEZERS

- INSTRUMENT KITS

- MARGIN MARKERS

- MEASURING CUPS

- MIXING BOWLS

- MIXING TIPS & GUNS

- MIXING TRAY ACCESSORIES

- MIXING TRAYS

- MPF DRIVERS

- OTHER BRUSHES

- PLASTER KNIVES

- PLIERS

- SAWS & BLADES

- SCALPELS & SCALPEL BLADES

- SCISSORS & CUTTERS

- SMILE LINE DRIVERS

- SMILE LINE HANDLES

- SMILE LINE VENEER ME

- SPATULAS

- STANDS

- SURVEYING

- TWEEZERS

- WAX INSTRUMENTS

- WORKING MATS

- INVESTING

- LIQUID CERAMICS MIYO

- MODEL MAKING

- PLASTER, STONE & PUTTY

- PLATING & TINTING

- POLISHING MATERIAL

-

PORCELAIN & STAINS

- ACCESSORIES

- BOND

- GC INITIAL INCISIO/INVIVO

- GC INITIAL IQ

- GC INITIAL LF

- GC INITIAL LISI

- GC INITIAL LUSTRE PASTES

- GC INITIAL MC

- GC INITIAL MC SETS

- GC INITIAL SPECTRUM STAINS

- GC INITIAL SQIN

- GC INITIAL TI

- GC INITIAL ZRFS

- GUIDES

- NORITAKE CZR

- NORITAKE EX3

- NORITAKE EX3 ADDMATE

- NORITAKE EX3 EXTERNAL STAINS

- NORITAKE EX3 INTERNAL STAINS

- NORITAKE EX3 LUSTER

- NORITAKE EX3 PASTE OPAQUES

- NORITAKE EX3 VALUE SHADE

- NORITAKE LIQUIDS

- OTHER STAINS

- UNIVERSAL MIXING LIQUID

- PREHEATING, CASTING & SOLDER

- PREPARATION & DUPLICATION

- PRESSING

- RELINING

-

ROTARY

- ACCESSORIES

- ACRYLIC

- ARBOR BANDS & ACCESSORIES

- BREDENT DIAGEN TURBO GRINDERS

- BRUSHES FOR HANDPIECE

- BRUSHES FOR LATHE

- BUFFS & MOPS FOR HANDPIECE

- BUFFS & MOPS FOR LATHE

- BURS FOR SILICONE

- DIAMOND DISCS

- DIAMOND FG

- DIAMOND GRINDERS

- DIAMOND HP

- DIAMOND SINTERED FG

- DIAMOND SINTERED HP

- DISCS & WHEELS

- DRILLS

- FELT POLISHERS

- GRINDERS FOR ACRYLIC

- MANDRELS

- MILLING TECHNIQUE BURS

- POLISHING

- PRE-SINTERED ZIRCONIA

- SCOTCH-BRITE

- SETS

- STANDS

- STEEL

- STONES

- TITANIUM

- TUNGSTEN CARBIDE

- STAINS - LIGHT CURING

- STUDENTS

- THERMOFORMING

-

WAXING

- ACCESSORIES & LIQUIDS

- ADHESIVE COATED

- BEADS & CRYSTALS

- BITE BLOCKS

- BLOCKING

- CASTING WAX

- CERVICAL

- CROWN WAX

- DIAGNOSTIC WAX

- DIPPING WAX

- INLAY WAX

- MILLING WAX

- OTHER WAX

- PERIPHERY WAX

- PREPARATION WAX

- SCAN WAX

- SET UP WAX

- STICKY WAX

- WAX FOR DENTURES

- WAX PATTERNS

- WAX PROFILES

- WAX RETENTIONS

- WAX SPRUES

- WAX WIRE

- WIRES, MESH, CLASPS & BARS

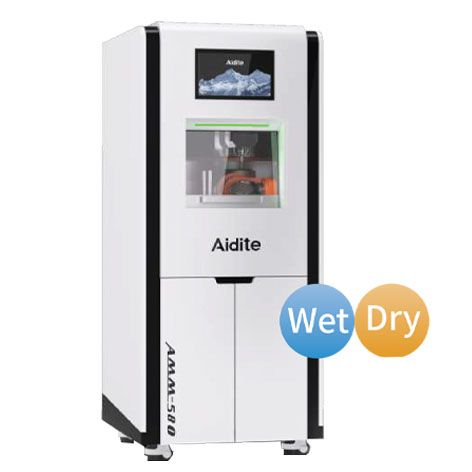

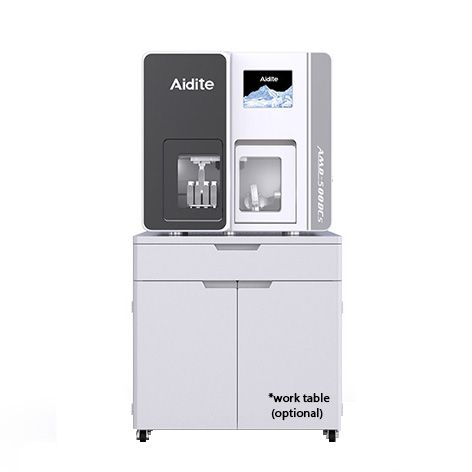

AMM-500DCS

Description

AMD-500DCs milling machine is a five-axis linkage automatic disc changing equipment. Suited for Zirconia, PMMA and Wax milling.

The equipment is matched with 8 disc changers, which can realize automatic disc changing for round-the-clock processing and production.

With an intelligent fixture identification function, more trays can be added, and intelligent identification improves production efficiency Matching C-shaped fixtures, improves material utilization by 30%.

Highlights

- Modular Structure

- Safety Door

- One-piece silicone dustproof

- Intelligent automatic fixture identification

- Control System

- Tool life management

Technical Data

| Platform | Aviation cast aluminum |

| Dimensions and weight | 826×793×835 (mm); 230kg (machine) |

| Processing methods | Dry milling |

| Number of tools | 10 |

| Automatic disc changer | 8 |

| Dust-proof | One-piece silicone, good dust-proof airtightness |

| Fixture Type | C-type fixture/C-type secondary fixture |

| Processing material thickness | 10-30mm |

| Processing material | Zirconia, WAX, PMMA, PEEK, HPP, Soft metal |

| Typesetting CAM software | Open |

| Rotation axis angle | A-Axis:±360°; B-axis:±28° |

| Motor | Servo motor |

| Barometric pressure | ≥6Bar |

| Power suppl processing Power supply Processing time Base time | 10-30mm |

Spindle

- Water cooled

- MAX:60000RPM

- AC 1500W

- 6mm/4mm collet

Function

- Intelligent fixture recognition function

- Tool life management

- Working Status Indicator

- Safety door

- Ion wind cleaning function vertical processing

Processing type

Crowns, bridges, implant bridges, veneers, inlays, open crowns, temporary crowns, etc.

- Dedicated for Zirconia, PMMA, and wax milling.

- Include Auto control Suction Unit

- Ideal for high-efficiency production with automatic disc changing. Equivallent to Roland 53DC